Solar Power Plant’s Cloud-Based Monitoring and Control

Striving for Power Output Reliability

A new solar power facility has begun operations in the hot and bright Tropic of Cancer. The solar panel installation field setting comprises a farm, a lake, and the roofs of nearby houses. Because solar panels that follow the movement of the sun can get 10% to 40% more energy than fixed panels, the system includes a central controller for altering panel angles. Furthermore, the facility must collect and communicate data on the present state of energy stability, as well as check the field temperature and activate the cooling system as needed. If power generation falls below the established specifications on a clear day with a moderate temperature, the system will automatically inform attendants to clean the solar mirrors.

Network Facility Challenges

Heat is a persistent issue at that latitude. Not only does high heat reduce the power-absorbing utility of solar panel wafers, but it can also damage or destroy the expensive electrical and networking equipment placed on-site. Another issue is the plant's distant location. The facility needed to be online and connected to the Cloud, but it was impractical to run network cables from the local ISP. SIM cards with public IP addresses are too costly for a 4G solution. Finally, the system must be able to communicate with a Modbus controller. Modbus is a communication protocol used for serial data transmission, and many machines at the solar plant use it.

As a result, the adopted solution had to overcome or work around these numerous barriers.

System requirements include:

- Remote field monitoring and control

- Ability to send alarms to mobile phones

- RS-485 interface and support for Modbus protocol

- Support for MQTT cloud protocol

- Microsoft Azure cloud

- Ability to operate in extremely high temperatures

- Dual cellular cards for redundancy

- Secure VPN tunnels

Network Solutions for Critical Infrastructure

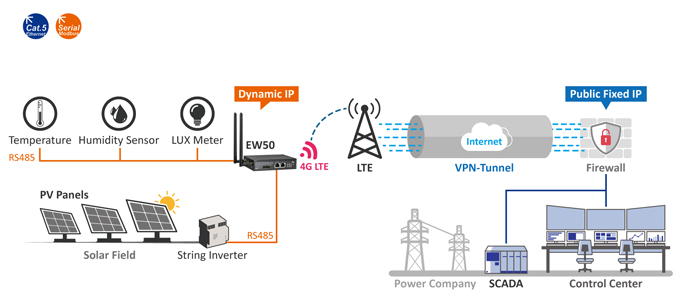

The EW50 is a smart industrial-grade gateway built for critical infrastructure and industrial applications. It offers dependable and secure remote connection for severe settings, offering operations and IT real-time visibility through remote monitoring. The EW200 is a sophisticated, feature-rich improvement of the EW50 and combines IEEE 802.11b/g/n/ac WLAN and 4G LTE cellular technologies.

Both devices support Ethernet, serial, DI/DO, and Modbus bridging, making them perfect for connecting to the site's numerous inverters, sensors, and other equipment. MQTT is, of course, supported. MQTT is a communications protocol that uses the publish-subscribe messaging model. It is the most fundamental method of cloud communication, and it is perfect for IIoT (Industrial Internet of Things) applications that require active notification.

The advantages of these two options were significant. Modbus RTU/ASCII is converted to Modbus TCP format by the Modbus gateway. The EW50, which is equipped with a floating IP SIM card, functions as a VPN initiator, connecting to a VPN server via a public fixed IP SIM card put at the power company's remote location for secure site-to-site communication. When the cellular connection is reconnected, the VPN is activated automatically.

The EW50 and EW200 feature toughened standards that provides consistent performance even under extreme heat.

Empowering Distributed Solar Power Plants

Solar power generation is becoming increasingly popular as a sustainable, clean energy source. The number of distributed solar plants being developed and put into service is projected to rise further. These plants require crucial monitoring and management, including real-time monitoring and messaging, panel tilt control, power prediction, and power control systems.

Traditional wired infrastructure for monitoring and control is sometimes impractical due to the cost inefficiency and limitations. The best option is to equip these facilities with proper 4G/LTE gateways. They support remote management via mobile phones and, if equipped with a DI/DO interface, you can remotely reboot an IPC using the DO relay mode. A serial interface on the gateways can eliminate the requirement for a PLC, lowering total costs.

Related products:

EtherWAN – " When Connectivity is Crucial "

► For more information, please contact: info@etherwan.com.tw